AUTOOL HTS678 Walnut Sand Blaster Cleaner Car Engine Carbon Deposition Cleannin

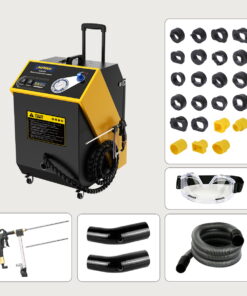

- Widely Applicable: Equipped with 23 kinds of adapters, suitable for a variety of models. Such as BMW, Volkswagen, Mercedes-Benz, GM, and VOLVO. NISSAN and so on.

- Service and Quality: We provide a three-year warranty. If you have any problems, please contact us, and we will respond within 24 hours! Online Support>>

For more discount and online support please click here.

AUTOOL HTS678 is a newly designed automotive de-carbon cleaner, it adopts an integrated design and is fully optimized to the corresponding product design modified by vacuum cleaners on the market.

It can solve the problem of carbon deposition in the intake and exhaust systems of automobile engines. This method is environmentally friendly, safe, and efficient. The working principle of the automotive walnut sand de-carbon cleaner is simple.

High-pressure airflow is sprayed into the engine intake pipe. The sand particles at high pressure and high-speed roll and collide in the closed intake pipe. This impacts the carbon deposits on the intake valve and cylinder wall. The walnut sand and carbon deposit mixture is then recovered into the sand storage bucket through a special joint.

What Is Walnut Sand?Walnut sand is made from walnut shells, which are processed through strict screening and classification after being broken. It is a walnut extract and serves as a metal polishing medium. Walnut sand has high hardness, high-pressure resistance, and wear resistance, with a microporous surface. It provides strong adsorption and sewage interception ability, and it does not cause corrosion or pollution.

Using walnut sand as an abrasive will not damage the workpiece’s surface or harm the engine when cleaning carbon deposits. The cleaning effect is remarkable, and the cost is low.

Some hydrocarbon olefin residues attach to the engine intake and cylinder when the fuel does not burn completely. It residues change into a hard black shell in high-temperature conditions, called carbon deposition.

Why Need Clean Carbon Deposition?

Carbon deposition will decrease the air-fuel ratio, cut down engine output power, increase fuel consumption, engine drastic shake on idle status all the thing will hurt the engine deeply. So normally we should clean carbon deposition after every 40000-50000 kilometer trip.

Air pressure up to 0.7mpa, 6bar or more air pressure.

- AUTOOL HTS678 is a special machine for the engine Intake pipe and intake valve back side.

- Close the intake valve, then spray walnut powder into the engine intake via air pump(not included), meanwhile, HTS678 will recycle walnut powder by vacuum.

- This is a closed loop. The walnut powder will impact carbon deposition on the inner wall of the intake pipe. After thousands of impacts, carbon deposition will be clear thoroughly

- A chemical cleaning agent will corrode the pipe and shorten the lifetime of the engine.

- Walnut powder is a pure natural polish material. It shows high performance in hardness, anti-pressure, and wear resistance.

- Walnut powder hardness was lower than metal but higher than carbon deposition. Take these advantages,

- AUTOOL HTS678 will clean the intake pipe and back side of the intake valve thoroughly but with no damage

- The high-precision engine system is sensitive to the foreign matter of the intake pipe, such as the BM-W Valvetronic system.

- That is why we need AUTOOL HTS678 to clean the carbon deposition in the intake pipe. AUTOOL HTS678 cleans one intake pipe each time, and the 6-cylinder engine should cleaned 6 times one by one(and so on).

- AUTOOL HTS678 is special for the intake pipe and intake valve back side clean only, if you want to clean carbon deposition on the injector/throttle valve/cylinder, please click here to shop for Injector Cleaners.

- The package does not include walnut sand and a high-pressure air pump.

- Walnut powder residual in the intake pipe will go to ashes at a high temperature after the engine starts.

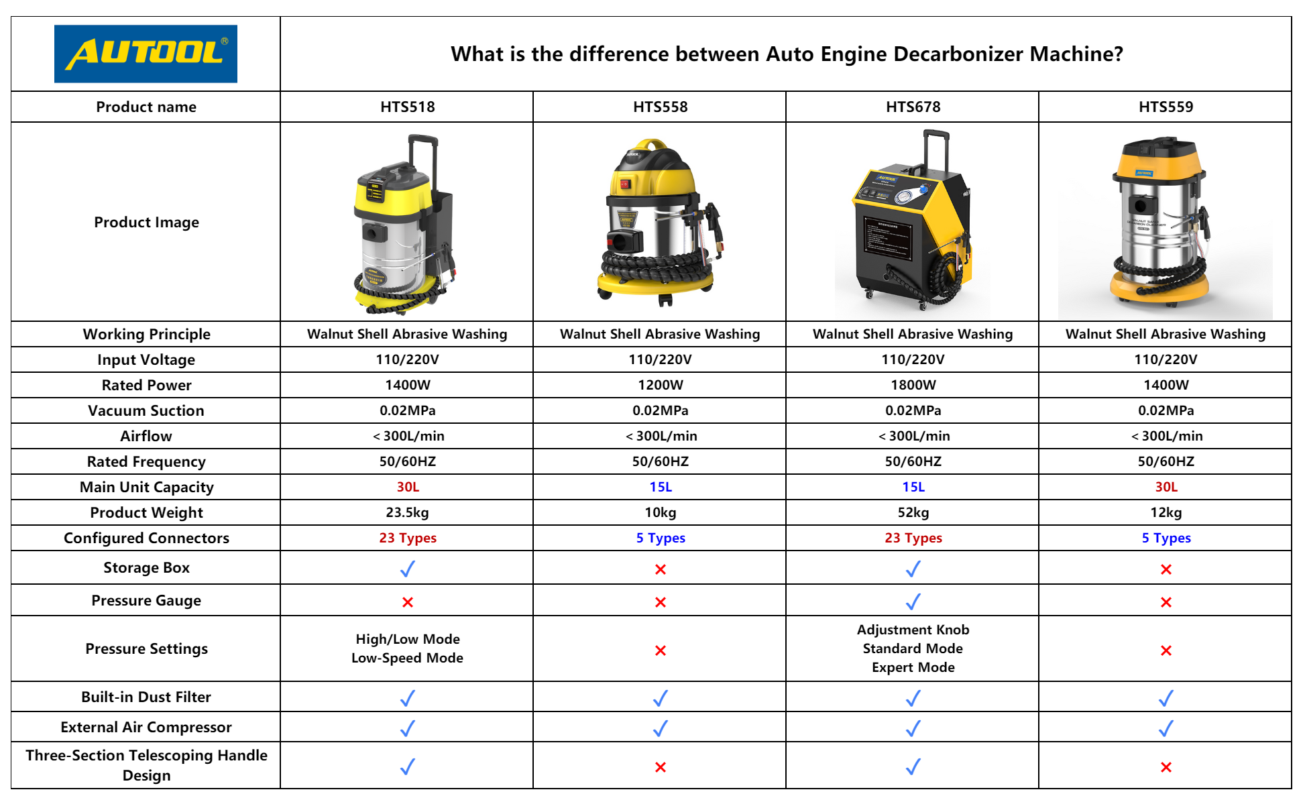

What is the difference between Auto Engine Decarbonizer Machine?

AUTOOL HTS678 Carbon Deposition Engine Cleaner Features

- Deep removal of carbon deposits: Deeply removes the highly sticky carbon deposits on the intake manifold, intake & exhaust valves. (Solve the problems of unstable idling, insufficient fuel combustion, and reduced air-fuel ratio.

- Intake manifold cleaning: Clean the intake manifold of the engine by sandblasting in sequence.

- Intake Exhaust valve cleaning: The sequential sandblasting process cleans the intake and exhaust valves without requiring disassembly.

- External air source: This enables the walnut sand grit to strike the carbon deposits more powerfully and efficiently.

- Built-in dust filter: It can separate the recovered walnut sand grit from carbon deposits for recycling.

- Integrated design: The walnut sand grit can be sprayed and recovered simultaneously, making the cleaning process efficient and convenient.

- Multiple adapters: Equipped with 23 kinds of adapters, suitable for a variety of models, such as BMW, Volkswagen, Mercedes-Benz, GM, and VOLVO.NISSAN and so on.

- 3-year warranty: For damage caused by non-human factors, we promise to resend parts for free within 3 years.

How To Use The AUTOOL HTS678?

- Step 1: Open the outer package and inspect all parts for any damage.

- Step 2: Pull the rod upwards, open the metal latches on both sides of the main unit, and swing the accessory box outwards. Take out the accessories, lock the accessory box, and proceed with the component installation as per the steps below.

- Step 3: Connect the end of the recovery particle hose with the tendon sheath to the main unit. Ensure the tendon sheath is clamped securely and confirm it is locked in place.

- Step 4: Select the appropriate fitting connector for the engine air intake, either the metal connector or the yellow silicone connector.

- Step 5: Attach the other end of the recovery pipe to the black transit-bend. Use the large bend with the metal model adapter and the small bend with the yellow silicone model adapter.

- Step 6: Open the top cover of the main unit. Rotate the handle of the filter cartridge counterclockwise, remove the filter cartridge, and check that the filter screen at the bottom is flat and not rolled over.

- Step 7: Add walnut sand into the sand storage bucket through the filler opening. The recommended amount is generally 3-5 kg.

- Step 8: Reinsert the filter cartridge and rotate it clockwise until it locks securely.

- Step 9: Close and secure the top cover of the main unit.

- Step 10: Move the main unit to the operating site and connect it to an external compressed air source, ensuring a pressure of no less than 0.7 MPa.

- Step 11: Switch on the standard mode of the device to start operation. For more advanced control, professionals may activate expert mode. Only one mode switch can be active at a time; the other must be turned off, or the air switch protection will engage.

- Step 12: Insert the sandblasting gun into the injection port on the black silicone bend of the recovery pipe. Pull the switch on the sandblasting gun to begin the carbon removal procedure. Adjust the throttle valve at the bottom of the gun as needed based on the workpiece and operating conditions to optimize spraying speed.

Be the first to review “AUTOOL HTS678 Walnut Sand Blaster Cleaner Car Engine Carbon Deposition Cleannin” Cancel reply

Related products

All Products

Reviews

There are no reviews yet.